Penetration firestopping systems and fire resistive joint systems are a passive means of fire protection. There is no movement or activation required. These passive systems are mainly used to compartmentalize a fire and keep it from spreading for a period of time long enough that occupants can evacuate the building and so firefighters can perform initial lifesaving tasks.

- Penetration Firestop Systems

- Fire Resistive Joint Systems

- The Difference Between Firestopping and Fireblocking

- F-Rating: Flame Rating

- T-Rating: Thermal Rating

- Firestop FT-Rating

- L-Rating: Smoke (Leakage) Rating

- Firestop Design Considerations

- Firestop Labeling Requirements

- Firestop Testing

- Firestop Engineering Judgments

- Firestop Management Systems

Penetration Firestop Systems

Modern buildings are full of various services that travel from room to room throughout a building. Electrical cables, data cables, and plumbing pipes are few of the items that pass through walls as they travel through a building. Engineers try to avoid having these services pass through fire and smoke barriers, but it is usually impossible. When a service must pass through a rated wall, penetration firestop systems are used to ensure the wall rating is maintined.

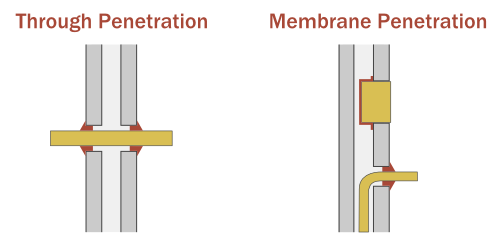

There are two types of penetration firestopping:

Through Penetration Firestop systems are those that protect penetrations that pass all the way through the barrier, whether it is a wall or a floor. In general, both sides of the penetration are sealed with the proper system.

Membrane Penetration Firestop systems protect penetrations that pass through part of the barrier, but not the entire barrier. Some examples are outlet boxes, sink drains, or conduit that leads from a back-box to the space above the ceiling. Membrane penetrations use the same products and similar details to protect the opening, but there are exceptions that allow them to be unprotected if the opening is small. Another way of saying this is that there are limits to the size and density of unprotected membrane penetrations within a rated separation.

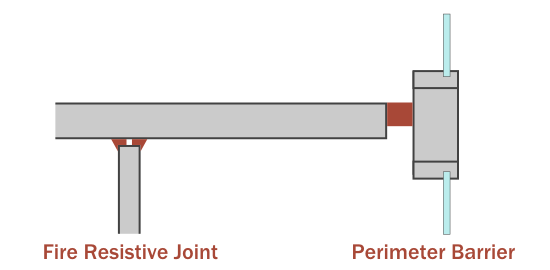

Fire Resistive Joint Systems

Fire resistive joint systems protect the joints or spaces installed within or between fire rated assemblies. The most common example of a fire resistive joint system is where the wall of a rated space meets the deck of the rated floor above. You will notice that these joints are protected with fire stopping, which tends to be a red colored sealant that spans between the two barriers.

The space between a rated floor slab and the inside face of a curtain wall system is a special case that is called a perimeter barrier. This is an important joint because the wall system requires a wider space than other wall systems and there could be significant movement in the joint, which could allow fire and smoke to pass through easily. The current standard used to test these systems is ASTM E2307: Standard Test Method for Determining Fire Resistance of Perimeter Fire Barrier Systems Using Intermediate-Scale, Multi-story Test Apparatus.

The Difference Between Firestopping and Fireblocking

This article is about firestop systems, which are specifically designed products that are combined into an assembly that is tested and confirmed to stop the spread of fire or smoke.

On the other hand, fireblocking is made from generic building materials (wood, mineral wool insulation, gypsum wall board, etc.) and is intended to prevent the spread of fire and smoke within the cavities of a building. In residential construction, where fireblocking is used most often, fire can spread in floor or wall cavities very easily so fireblocking is installed.

It is important to note that fireblocking is not a tested assembly and there are no referenced standards; however, some jurisdictions require fireblocks to meet ASTM E-136: Test Method for Behavior of Materials in a Vertical Tube Furnace at 750˚C.

F-Rating: Flame Rating

The F-Rating for a firestop system indicates the number of hours that the assembly will prevent flames from passing through to the other side of the barrier.

T-Rating: Thermal Rating

A firestop system’s T-Rating indicates the number of hours until the ambient temperature on the non-fire side of the barrier rises by 325-degrees Fahrenheit when the protective is subjected to fire.

Firestop FT-Rating

Many firestopping systems are tested for both thermal and flame resistance. In this case, the design will have an FT-Rating. The FT-Rating is the number of hours that a system will prevent the passage of flame as well as preventing a 325-degree-Fahrenheit temperature rise – it will always be the lesser of the F and T Ratings. For instance, if a system receives a 1 hour T-Rating and a 2 hour F-Rating, the system will receive an FT-Rating of 1 hour.

L-Rating: Smoke (Leakage) Rating

The L-Rating for a firestop system indicates the amount of air that can pass through a protective. The number represents the leakage rate in cubic-feet-per-minute. The L-Rating is an optional test under ANSI/UL 1479 (Fire Tests of Through-Penetration Firestops) so assemblies may not receive an L-Rating. Since many systems are not tested for leakage, it is important to know if you need a system to have an L-Rating.

Firestop Design Considerations

In general, the architect’s specifications provide requirements and it is the responsibility of the installing contractor to ensure that the correct system is selected and properly installed. However, there are some things for architects to think about when they are observing construction.

The annular space is the area between the penetrating object and the barrier construction. Each firestop system has limitations for the annular space so if an architect or inspector observes a condition where the annular space is excessive, then further investigation is required.

Load bearing fire stopping or joint systems are a special case scenario that needs to be reviewed with a certified installer or engineer. Most fire stop manufacturers have load bearing assemblies, but there are strict guidelines for proper usage and installation.

Understanding the amount of movement, especially in fire resistive joint systems, is critical for proper protection. If you anticipate moderate or excessive movement of a joint it is important to have the system reviewed by a fire stopping engineer.

Firestop Labeling Requirements

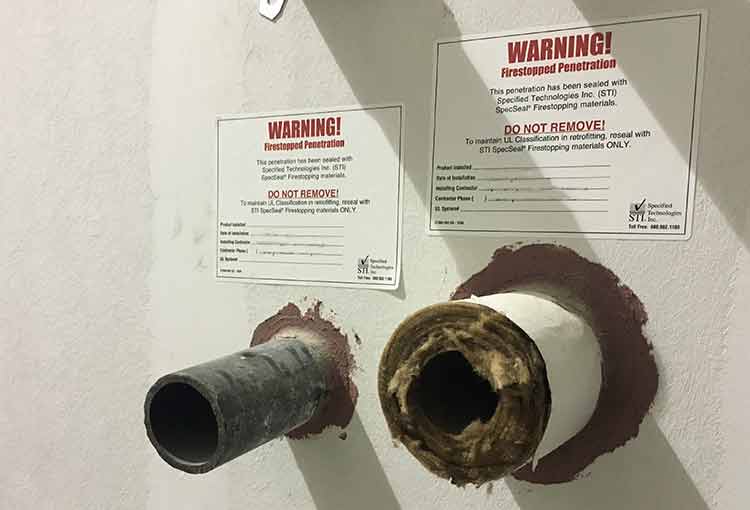

The International Building Code (IBC) requires that fire walls, fire barriers, fire partitions, smoke barriers, and smoke partitions be permanently identified with stenciled lettering or other labels. However, penetrations are not required to be identified or labeled.

While labels are not required, many installers provide them and some building managers require them. The labels are specific to each manufacturer, but they typically include the installation date, the installer’s name, the detail used, and any engineering judgments that apply. The label will identify the penetration as fire resistance rated fire stopping and indicate that tampering with it can affect the system performance.

Firestop Testing

***Always check your local codes to confirm the testing procedures required. The following information is general in nature and must be confirmed with the local building codes and the Authority Having Jurisdiction.

Through Penetration Firestop systems are usually tested according ASTM E814: Fire Tests of Through Penetration Fire Stops. The firestop system shall have an F-rating equal to or more than the rating of the wall penetrated. Floor penetrations shall have an F-rating and T-Rating of at least an hour, but not less than the fire resistance rating of the floor.

Fire resistive joint systems are generally tested to meet UL 2079: Tests for Fire Resistance of Building Joint Systems. The joint systems shall have a tested rating of not less than that of the required rating for the assembly they are a part of.

As we stated above, perimeter barriers are tested using ASTM E2307: Standard Test Method for Determining Fire Resistance of Perimeter Fire Barrier Systems Using Intermediate-Scale, Multi-story Test Apparatus.

Firestop Engineering Judgments

In many cases, the various tested firestop systems are not applicable to particular field conditions. If a tested system does not exist, an engineering judgment can be obtained. The engineering judgment, often referred to as an EJ, is prepared by a manufacturer or engineer and provides a new detail that hasn’t been tested, but that is judged to be effective based on the engineer’s knowledge and proper interpolation of other tested systems.

It is critical that these EJs be prepared by an experienced engineer. The EJ will include a sketch of the detail to allow proper installation and will provide some language about where it is appropriate for use.

Firestop Management Systems

Most manufacturers of firestop systems have developed databases that allow building managers to keep detailed records for the many penetrations and joints that are within their facilities. These systems allow a facility manager to maintain code compliance information and manage maintenance and installations. The systems are usually web-based so that information can be pulled up on a tablet or mobile device when in the field.

The biggest issue with these systems is that they are proprietary to each manufacturer, but large facilities tend to have firetop systems by a number of different manufacturers. Selection of a firestop management system should be made carefully.