A common misconception with wood decay is that it only occurs because of exposure to moisture. Decay actually occurs because of a combination of moisture, moderate temperatures, and a supply of oxygen. These three factors promote the growth of fungi within the wood tissue, causing it to decay. Wood preservative treatments (aka Pressure Treated Wood) help prevent this decay.

- Decay Resistant Woods

- Pressure Treated Wood for Rot Prevention

- Applied Treatments for Rot Prevention

- Types of Wood Preservatives

- Rot Mitigation: Addressing Rotting Wood

- Appropriate Fasteners

- Staining Pressure Treated Wood

- Specifying and Identifying Treated Wood

- Treated Wood Health and Environmental Hazards

The two primary types of fungal decay are known as wet rot and dry rot. One of the main differences between wet rot and dry rot is that wet rot needs a higher moisture content to grow. Wet rot fungus likes to grow on timber with a high moisture content of around 50% and above, while dry rot will germinate at a lower timber moisture content of around 20% to 30%.

Dry rot is a serious form of decay that can continuously destroy timber and other property fabric. Wet rot is more common and more localized, usually only affecting timber at the source of a leak or other moisture. However, wet rot can be serious if structural wood members are left untreated or if the water source spreads.

In addition to fungi, wood can be damaged by insects like termites and carpenter ants. This damage can occur in dry areas and can cause significant structural damage.

It is necessary to know the nature of the insect or fungi that attack wood and the conditions necessary for their growth. Then, you can choose a resistant wood, pre-treat the wood to prevent the start of insect infestation and fungal growth, or treat the wood after the fungal growth has commenced to stop the spread.

Naturally Decay Resistant Woods

Decay resistant woods including cypress, cedar, black locust, and redwood can be used to reduce the likelihood of wood decay. These timbers are predominantly used in exposed areas such as shingle siding, external decks, and balconies. They require no treatment to resist decay.

Pressure Treated Wood for Rot Prevention

Pressure treating wood involves forcing chemicals deep into the wood. This treatment is carried out using a vacuum cylinder. The wood is placed inside the vacuum and air is drawn from it to completely dry out the timber. Then the cylinder is flooded with the selected preservative at a high pressure to ensure it is forced deep into the wood. The wood is then left to dry before it is given a topcoat, if required.

Pressure treated wood protects the wood throughout the entire timber (including deep inside) which makes it less susceptible to rot, parasites, and insect attack.

Applied Treatments for Rot Prevention

Another method of treating wood is by applying topical liquid treatments. They involve applying different types of liquid preservers which may contain biocides, insecticides, pesticides, etc. These are normally applied to exterior timbers to protect them from the elements, insects, and UV light protection.

These tend to be applied with a brush or sprayer, with the chemicals soaking into the wood to provide the desired protection to the wood. The main problem with applied treatments is that they only soak part of the way into the wood so the timbers may not have complete protection, especially on the non-treated side.

Types of Wood Preservatives

There are two main types of wood preservatives, oil-borne and water-borne chemicals. Both include a chemical mixture that is either applied or impregnated into the wood as described above.

Oil-Borne Preservatives

Oil-borne preservatives such as creosote and pentachlorophenol (PCP) can be applied to protect the timber from decay. However, both of these have severe health risks and should generally be avoided.

Creosote was predominantly used as a treatment for outdoor wood structures to prevent rot and is added via pressure treatment. It is still used in some settings, but is no longer allowed for residential use.

PCP can be used as both a pesticide and a disinfectant and can be applied by spraying, brushing, dipping and soaking the wood or by pressure process method. This involves placing wood in a pressure-treating vessel where it is immersed in PCP and then subjected to applied pressure.

Oil-borne products including copper, such as copper naphthenate, have been deemed to be safer alternatives to creosote or PCP. However, care should still be taken since the health risks are still not fully known.

Waterborne Preservatives

Water-borne preservatives include alkaline copper quaternary compounds, copper azole, ammoniacal copper zinc arsenate, copper citrate, and copper HDO.

Water-borne preservatives are usually among the cheapest options available to consumers. However, their greatest drawback is that the wood can be compromised due to the presence of water in the preservative. Application can, and often will, lead to swelling and/or warping of the wood being treated, especially if it is already porous. The heavy metals (copper) in the chemical may also be hazardous to health and environment.

Chromated copper arsenate (CCA) was the traditional chemical used to pressure treated wood. You may be familiar with the green tint and wet feel of this type of treatment. However, CCA has been phased out of residential construction starting in 2003 due to health and environmental concerns surrounding the chromium and arsenic in the chemical.

Borate is a preservative made from boric acid. It is considered a safer alternative to other preservatives since it doesn’t contain heavy metals like copper. However, the problem with borate is that it can leech out of the wood when repeatedly exposed to large amounts of water.

Copper Azoles have become the standard in pressure treated lumber and there has been an evolution of the products.

Copper Azole Type B (CA-B) had a mix of copper and an azole as the two primary protectants.

Copper Azole Type C (CA-C) is the most common form of preservative and is listed in the AWPA U1 standard. This is a solution of dissolved copper with multiple azoles. CA-Cs are approved for use in all types of construction and do not carry any special EPA restrictions for handling the wood.

Micronized Copper Azole (MCA-C) treated lumber is becoming increasingly popular as a wood preservative. Instead of dissolving, the copper is finely ground and then suspended in the liquid (with azoles) that is used to treat the wood. While it doesn't have an AWPA U1 specification status (see below), many manufacturers have had their chemicals reviewed by the International Code Council Evaluation Service and they have received evaluation reports that indicate compliance with the International Building Codes. Architects and specifiers should make sure their selected MCA-C products have a current ICC-ES evaluation report.

New Preservative Technologies

Due to the health and environmental risks with traditional wood preservative chemicals, a number of other wood preservation methods are being tested with varying levels of success. Sadly, the hazardous chemicals appear to outperform the less hazardous versions, but there are some promising options including acetic anhydride, linseed oil, and furfuryl alcohol.

Rot Mitigation: Addressing Rotting Wood

The best option for addressing wood rot is to replace the damaged members and eliminate the cause of the problem. However, there are also circumstances where the rot is minimal and you want to avoid replacing the affected wood.

The first stage of treatment is getting a specialist to diagnose the cause and type of decay present in the timber and to help determine if replacement is necessary.

To solve issues with wet rot, it is important to first identify the source of moisture and stop the cause of the dampness. Alternatively, you can isolate the timber from the damp source before treating the affected areas. In many cases you will need to replace the affected timbers. However, in some cases you can stop wet rot by treating the timber with a fungicide. Treating wet rot involves applying a fungicide during and after the drying out period. These treatments will stop further deterioration as long as the source of the water ingress has been stopped.

Dry rot is more difficult to deal with, requiring the timbers to be treated with a fungicide and for surrounding materials to be sterilized with a biocide. As with wet rot, structurally compromised timbers also need to be replaced.

Insect infestations such as woodworms or termites are generally eradicated from timbers by applying an insecticide. Again, structurally compromised wood must be replaced once the insect infestation is fixed. Then regular preventative treatments should continue.

Resins or other wood infill materials can be used to make cosmetic repairs to the affected timbers, but should never be used to fix structural components that have been damaged.

Appropriate Fasteners

The chemicals used in wood preservation can corrode hardware like nails, screws, hangers, etc. For instance, galvanic action may cause the copper in many preservatives to interact with aluminum, steel, or zinc. Therefore, it is important to use properly coated fasteners to prevent corrosion. Companies who make the wood preservation chemicals provide guidance to architects and specifiers on selecting appropriate fasteners, which may vary based on the chemical used. Some companies indicate that regular fasteners and hangers can be used so it is always best to check their documentation.

Pressure treated wood with direct contact to aluminum (like flashing) should be avoided to prevent corrosion. However, there are some manufacturers with products that can be used in direct contact with aluminum so check with them prior to finalizing your details. An alternative approach where aluminum flashing is required, is to separate the aluminum and pressure treated wood with a waterproof building fabric or paper.

Since water is a major contributor to galvanic action, you may consider countersinking and plugging the fasteners. This eliminates a location for water to pool in contact with the wood and metals.

Staining Pressure Treated Wood

As far as adding color to pressure treated lumber, this US Forest Service article Finishes for Wood Decks, indicates that it is best to use semi-transparent oil-based stains on wood treated with preservatives. New wood preservatives have less of a green tint, which should help stains to be more true in color. However, it is important for an architect to see final samples of the stained wood prior to installation.

It is not advisable to paint pressure treated wood because the moisture content is high so the paint won't bind as well to the wood and the paint will likely peel. You can opt for kiln-dried (KDAT) pressure treated wood, which has a lower moisture content if you want to paint treated wood. However, a better solution is to use a naturally rot-resistant wood (cedar, teak) if you plan to paint it — of course, these are more expensive and generally look better unfinished.

Painting untreated wood will provide some level of surface protection from the weather, however it will do nothing to prevent a fungus or insect attack. The protection received from paint can be increased by applying a liquid wood preservative prior to painting, which can help protect the wood from insect and fungus infestation. Treating all sides of the wood, including ends, with an oil based primer and preservative helps provide this extra protection.

Specifying and Identifying Treated Wood

The American Wood Protection Association was founded in 1904 as the standard-setting body for the protection and preservation of wood.

The AWPA developed a Use Category System, introduced in 1999, to identify biodeterioration hazard levels for treated wood products. This system assists specifiers and users in selecting the appropriate treatment for their particular wood item. Home owners and architects alike will find this simple Use Category diagram PDF to be helpful when selecting the correct lumber.

Preservative treated wood is governed by the AWPA Standard U1, which is used as a reference in the ICC codes. Specification involves calling for Standard U1 plus the relevant Use Category. This is described on the AWPA document, How to Specify Treated Wood Products.

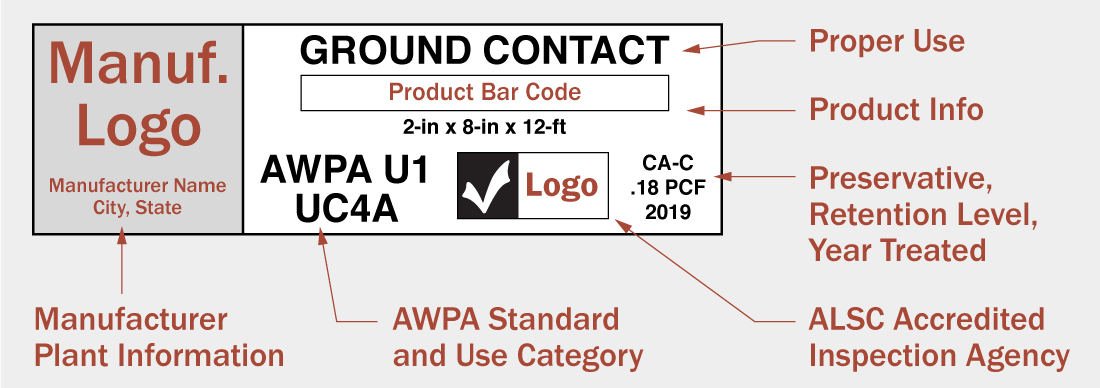

Treated wood from reputable sellers includes a tag stapled to the end of the board. This tag provides information on the treatment, including: manufacturer, acceptable exposure, AWPA standard, Use Category, inspection agency information, type of preservative, and the retention (amount of preservative in the wood).

Some pressure treated wood products are not compliant with AWPA U1, but can be used in code compliant projects. For instance, as described earlier in this article, micronized copper azole (MCA-C) is an acceptable wood preservative since it has been evaluated by the International Code Council Evaluation Service. Architects should confirm that the non-U1-compliant products they specify have the appropriate ICC-ES Evaluation Report and that the report is current. It is advisable that this be included in the project submittals for record.

Pressure Treated Wood Hazards

We’ve discussed a number of health and environmental problems caused by the chemicals used in wood preservatives. A detailed analysis of these problems is far beyond the scope of this article, but the US EPA provides an Overview of Wood Preservative Chemicals.

It is critically important that carpenters and do-it-yourselfers understand how to protect themselves from the chemicals in pre-treated wood products. All manufacturers have safety data sheets that help you understand what personal protection you need. Check the end tag on your wood to find the manufacturer and contact them for the relevant information.

Pressure treated wood should never be burned. In addition, treated wood (especially those with older preservatives) should be disposed properly to avoid contamination of the disposal sites. Contact your local authorities for disposal information.

At the same time, untreated wood can also lead to health risks. A person left exposed to the effects of rotting wood for a lengthy period can develop respiratory problems such as asthma and other lung conditions. The presence of rot in wood implies unhealthy levels of damp and moisture present in a building, which can be linked with other conditions such as colds, flus, hyperthermia and pneumonia. There is also the obvious increased risk to health with the potential structural failure of the building when severe wood decay is left unchecked.