Steep sloped roofs are common on residential buildings, but are also used frequently on commercial projects. There are a number of steep sloped roofing systems on the market so architects have a variety of aesthetic options to choose from. This article covers the most common materials available.

What Pitch is Considered a Steep Roof?

Steep slope roofs are those with a pitch greater than 3:12, meaning there are three or more units of rise per twelve units of run. Steep roofs can be nearly vertical, but eventually the surface becomes a wall or fascia. For more information on slope notations, check out our article about calculating slope.

| ROOF GRADIENT | DEGREES | PERCENT |

|---|---|---|

| 4 : 12 | 18.43° | 33.33% |

| 5 : 12 | 22.62° | 41.67% |

| 6 : 12 | 26.57° | 50% |

| 7 : 12 | 30.26° | 58.33% |

| 8 : 12 | 33.69° | 66.67% |

| 9 : 12 | 36.87° | 75% |

| 10 : 12 | 39.81° | 83.33% |

| 11 : 12 | 42.51° | 91.67% |

| 12 : 12 | 45° | 100% |

The table above doesn't show every option. As mentioned, slopes can be nearly vertical. Therefore, you can have a 24:12 roof slope, like on a church steeple, or even steeper.

Slopes of 3:12 and shallower are considered flat or low-slope roofs. Low slope roofs use a waterproof membrane system, which is discussed in our article Types of Roof Membranes for Flat or Low-Slope Roofs. Steep slope roofs are not waterproof - rather, they relay on overlapping materials and gravity to shed water.

We have other articles where you can learn more about roof shapes. Each of the shapes depicted there can be combined on a project to develop complex roofs.

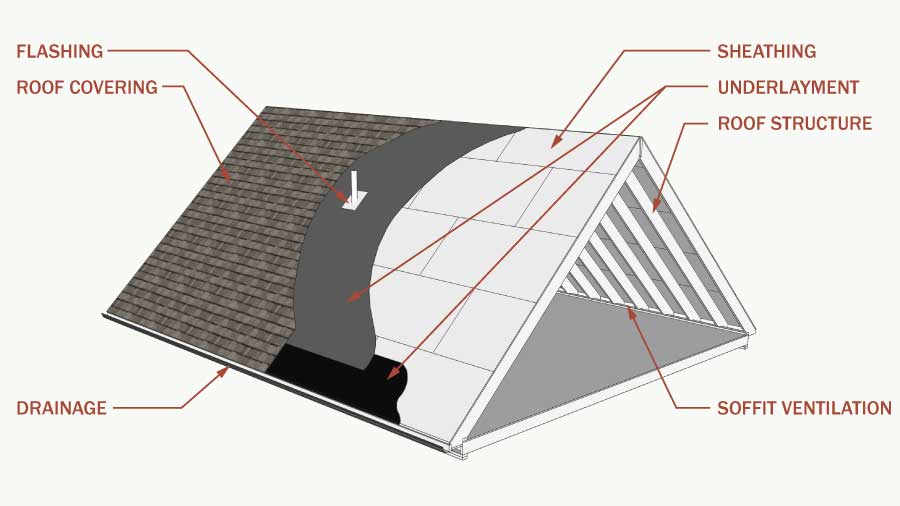

Sloped Roof Components

There are a number of critical components to a steep roof. The main job of the roof is to keep the natural weather elements out. As mentioned earlier, steep slope roof systems are not waterproof; they keep water out by shedding it.

The first element is the roof structure. The most common structural system used is the roof truss or a stick-built rafter system. Steel framing systems are far less common, especially in residential construction.

The next component is the sheathing that goes on top of the roof structure. This provides a base to attach the roof covering. Generally, this is plywood or oriented strand board (OSB). Older homes used wood boards or planks.

An underlayment is applied on top of the sheathing. This comes in many forms, but roofing felt is most common. The felt comes in 36" wide rolls made from a polyester or other composite material and is mechanically fastened to the sheathing. The felt serves as a final protection to help shed water should there be a problem with the roof cover. It also helps prevent telegraphing of the sheathing joints through shingles. Lower slope roofs (3:12 or 4:12) may require two layers of underlayment materials. Underlayments are usually dictated by the roof covering manufacturer so it is important to select the correct product to maintain the roof warranty.

In addition to roofing felt, certain climates require other underlayment products. For instance, roofs in cold climates benefit from an ice and water shield. This is self adhesive sheet applied to the bottom portion of the roof to prevent damage from ice building up behind the lower layers of shingles.

The next component of steep sloped roofing systems is flashing. Sheet metal is most common, but other flexible composite materials like rubber are also used for certain conditions. Flashing is used to keep water from finding its way through susceptible joints like vent penetrations and roof valleys.

The roof covering goes on next. There are a series of options when it comes to materials, which are discussed in more detail below. The primary function of the roof covering is to shed water off the roof. They are not meant to be waterproof, which is why the roof slope is important. We rely on gravity and overlapping covering materials to divert water down the roof to the drainage components.

Drainage components collect water as it is shed from the roof and divert it away from the rest of the building. While the roof covering and flashing can be considered a drainage component, we are mostly talking about gutters and downspouts.

Finally, ventilation is an important part of roofing systems. Dark colored roof coverings can get very hot due to solar gain. This heat transfers into the void space (attics, crawl spaces, etc.) within or below the roof structure. Excessive heat can cause problems in all climates so it is important to provide a means for it to escape and provide a better balance with the ambient air temperature. The idea is to use natural convection to let hot air out of the roof at high points, while allowing cooler air to enter from low points like soffit vents. Ventilation products are usually static, but they can also be fan-powered in extreme situations.

The NRCA Steep Slope Roofing Manual provides a lot more detail than we discuss above. While it is targeted to roofing system installers, it can provide a wealth of information for architects and engineers.

Steep Slope Roofing Materials

There are a number of important considerations that architects must analyze as they select materials. The roof covering can dictate the underlay, structure, ventilation, etc. Be sure to review product literature so that a fully warrantied system is designed and installed for your client.

Material Selection Considerations

Climate will heavily influence selection of roof covering materials. Hot and sunny climates will benefit from light colored products (i.e. high albedo). Cold climates require ice shield underlayment to prevent ice dams from backing water up into the building during the freeze-thaw-freeze process. Locations susceptible to forest fires should consider non-combustable materials like slate or metal. Very windy locations require special attachment details or products designed to prevent uplift.

Aesthetics also play a role in selection of materials. Both the client and architect have materials they prefer based solely on appearance. However, do not let appearance override climactic issues; otherwise, you may have a leaky roof.

Both material and labor costs should be considered. Heavier and bulkier materials require more labor. Availability of materials near the project site is also important. Local contractors can assist with this aspect of material selection.

Durability of the roof covering is also a factor, especially since certain materials last longer but may cost more. The lifecycle cost is important to consider. Some natural materials like wood can degrade faster than composite materials if they are not maintained properly.

Finally, the lifecycle of the materials has become more important to clients (and to the industry in general) as we improve the sustainability of the our projects. Traditional asphalt shingles are made with petroleum products and cannot be easily recycled, but newer shingles can be collected and recycled when it is time to replace the roof. Other materials like wood will break down, but chemical treatments for wood can be hazardous. Composite roof coverings are often made from recycled materials.

Warranties

Most natural products like wood and slate will not offer a warranty on the material. Other products offer warranties, but they are very limited in scope. Architectural Graphic Standards (Twelfth Edition) indicates,

...warranties are primarily a means for manufacturers to limit their liability, rather than to protect an owner. Furthermore, some products are promoted as having extremely long warranty periods, but the fine print limits coverage to replacement of defective materials on a prorated cost basis to the original owner. Defective installation is not covered, nor is there any value available for the cost of labor to make repairs.

Be sure to carefully read the warranty so you are not swayed by a very long warranty period when selecting materials.

Wood Shakes and Shingles

Wood shakes and shingles are manufactured from wood species that are naturally resistant to moisture and UV light. Red cedar is the most common, but a few other species are available. Shakes are either entirely hand-split from logs or are made from a combination of hand-splitting and cutting with a saw, which will leave one side with a smooth texture and the other with a more natural rough texture. Shingles are cut with a saw so both sides are smooth.

Shakes and shingles are mechanically fastened with galvanized nails and care must be taken to make sure the nail is not over-driven, which will crack the wood and make it less durable.

Depending on the wood selection, shakes and shingles can be left unsealed and allowed to weather through exposure to Mother Nature. However, sealants and stains can also be used to help maintain a more uniform finish or to keep the wood from taking on a natural weathered appearance. Fire-resistant chemicals can also be applied to help reduce the risk of fire.

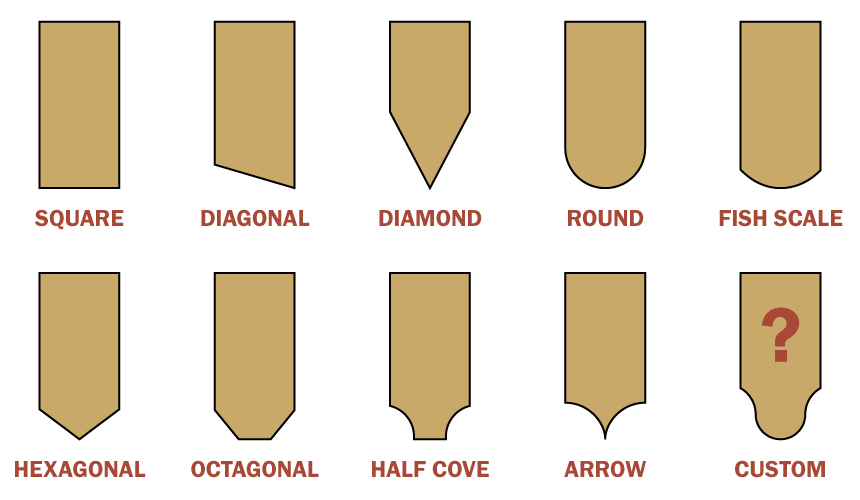

The most common shape of the shingle/shake is a tapered square. Shingles can be manufactured to other shapes like rounded, hexagonal, octagonal, and more. Shingle shapes can be combined to create more dramatic accent patterns where building occupants can see the roof up close.

Wood shingles/shakes will provide a durable roof with a lifespan of 20-25 years. Material and installation costs are higher than typical asphalt singles, but less expensive than slate or tile roofs.

Slate Roofing

Natural slate roofs are extremely durable and can last from 20 to over 75 years depending on the grade of slate chosen. There are a number of color options including black, blue-black, gray, green, purple, and red. Since it is a natural material, expect variation in the color.

Slate roofs are heavier than other materials so it is important to account for this when designing the structure of the roof. Also, keep in mind that underlay materials need to be compatible with the weight of the slate as well as the lifespan - it is a good idea to use a heavier underlay so it will last as long as the tiles and won't be cut or torn during installation.

Slate tiles are generally pre-punched with two holes at the top for mechanical fasteners. Like with wood shingles, the fasteners should resist corrosion and should be carefully driven to allow expansion and contraction of the tiles without cracking them.

Imitation slate is also available. There are many material options for imitation slate including recycled rubber, mineral fiber, and ceramic. These products are often lighter and easier to modify in the field so they come at a significant cost savings. However, the lifespan of imitation slate may be shorter.

The cost of a slate roof is near the top of the scale compared to other options, especially since the underlying structure also needs to be more robust than for lighter materials.

Tile Roofs

Roofing tiles come in two typical materials: clay and concrete. Both can be very durable, but are also fairly heavy and require careful structural planning. They are either installed with lugs that attach to battens or are nailed through pre-drilled holes in the tile.

Tiles come in three main shapes. Flat tiles are similar to slate, but thicker. Barrel tiles are half-round and are installed in an alternating pattern of round end up/down to shed water. S-shaped tiles are an interlocking shape that includes half of an up and half of a down tile.

Clay tiles are less porous than concrete so they are usually more durable. The finished tile color is dependent on the color of the clay used to form the tile and will vary since it is a natural material. Clay tiles can be glazed to improve durability and allow for a wider range of more consistent colors.

Concrete tiles are less common than clay, but they can be pigmented to virtually any color. While they are more porous (less durable), this can be addressed though glazing the tile.

In addition to clay and concrete tiles, metal tiles that mimic traditional clay tiles have been developed. These are discussed in more detail below.

Metal Roofing

There are two types of metal roof: tiles and standing seam. Both are made from thin sheets of metal so they are lighter than some other materials, while still being extremely durable.

Metal roofing tiles were developed to simulate clay tile roofing, but newer products can also simulate cedar shakes or slate. The tiles are made from roll-formed steel that allows for many different profiles. The visible side is then coated with a resin that has finely crushed stone granules integrated into it. The back side of the tiles are coated with a durable paint.

The tiles are usually mechanically fastened to battens with an interlocking design. The entire system is significantly lighter than other tiles and can be installed much faster. The lifespan of metal tile roofs is on par with other tiles, but can exceed 50 years depending on the product.

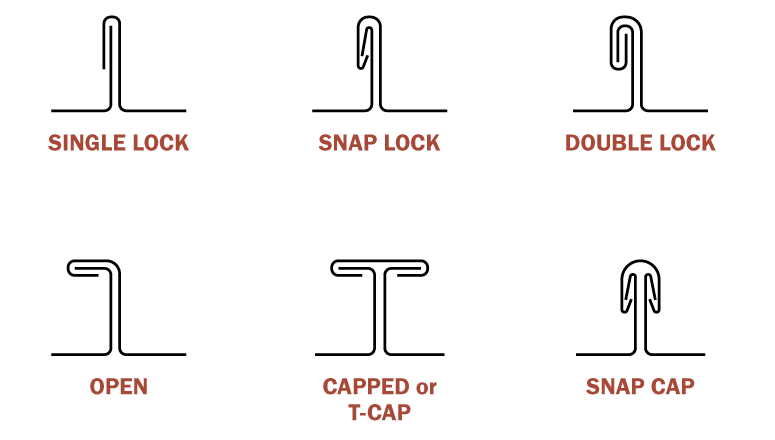

Another popular metal roof is the standing seam metal roof, which is made from sheet panels formed on a break and then interlocked by folding adjacent panels together to create a watertight seam. The profile of the seam creates a shadow line on the roof for depth and there are a number of seam types, which are shown below.

Finally, the batten seam roof is created with wood battens where the seams are formed over the battens to create a wider profile.

Asphalt Shingles

Asphalt shingles are the most common roofing for steep sloped residential installations across North America. They are cost effective, easy to install, and relatively low-weight. Each manufacturer offers an array of color selections including lighter colors that help reflect sunlight. Asphalt shingles have a lifespan of around 15-20 years.

The shingles come in sheets that are 36" wide and 12"-14" tall. They are made from either fiberglass or an organic felt that is impregnated with asphalt and coated with ceramic, stone, or sand granules. The asphalt provides the waterproofing barrier while the granules protect the felt from UV rays and debris.

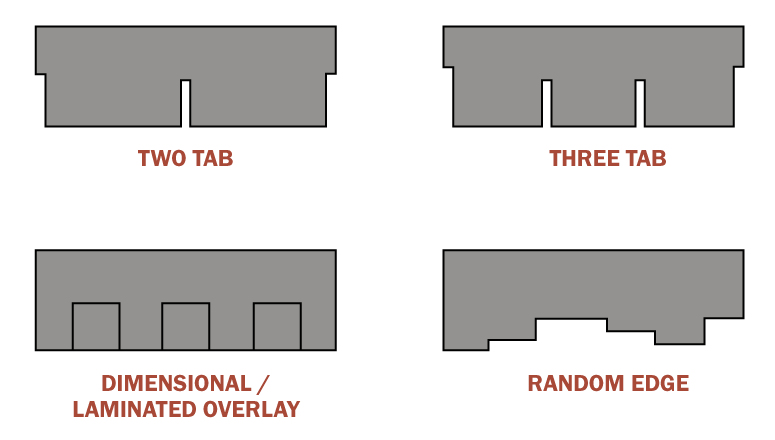

The tiles come in four main shapes: two tab, three tab, laminated overlay (also called dimensional), and random edge. Each tile has a line that indicates the nailing location and a sealant strip to help prevent water from running up the back of the tile.

Integrated Photovoltaic (Solar) Roofing

A number of companies are developing roofing materials that have integrated photovoltaics that capture energy from the sun for use in the home or building. The shingles are significantly more expensive to install, but the idea is that the energy produced over the lifetime of the roofing offsets the initial cost.

These products are relatively new and there aren't many roofing companies familiar with the installation. In addition, the shingles are not as efficient as conventional solar panels mounted over top of the roofing material. However, it is expected that integrated solar shingles will become more popular as the costs come down and the products become more efficient and reliable.

Sources

National Roofing Contractors Association: https://everybodyneedsaroof.com

Architectural Graphic Standards Twelfth Edition, American Institute of Architects