A good construction schedule is crucial for any project, from simple jobs like roof replacement to complex endeavors such as building a skyscraper. No matter what the project, it is important to know what needs to be done (planning) and when it needs to happen (scheduling). Equally important to know is how to accomplish this process. The sections below provide some insight and examples of planning and scheduling a construction project.

Project Planning

In its most basic form, project planning consists of determining the milestones of the project and outlining the individual tasks that need to occur in order for the milestones to be completed. For example, one milestone during construction of a residence is completion of the building foundation. The construction of the foundation can be broken down into individual subtasks such as:

- Clearing the building site

- Excavating the soil to foundation depth

- Placing reinforcing bar and creating forms for the upcoming concrete pour

- Pouring and finishing the concrete

- Providing a concrete curing period

- Removal of the concrete forms

All of the above tasks need to occur in the specific order listed in order for the foundation to be built. A length of time, or duration, will be established for each sub task so that the overall time frame required to complete the foundation can be determined. The duration for completing specific tasks is usually established based on past experience or by using references such as construction estimating manuals. Once the order of tasks is established and the duration selected for each, a construction schedule can be created. Some of the more common techniques for construction scheduling will be covered below.

Critical Path Method

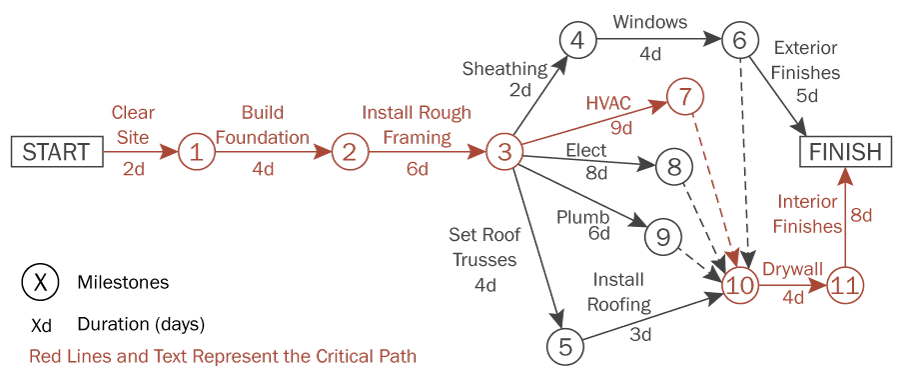

The critical path method, abbreviated as CPM, is the most commonly used type of scheduling technique in the construction industry. The critical path method is built around the use of predecessors and successors for each construction task needed to accomplish the job. Most tasks (except the initial task) will have one or more predecessors that need to be accomplished before that task can start. If we select a certain task, such a framing a house, we need to determine what must occur before the framing can be constructed. In this case the ground floor slab will need to be finished before the framing can be placed on top of it. Therefore, creation of a ground floor slab is the predecessor of the house framing task. Conversely, framing the house is a successor of the ground floor slab construction.

Following the placement of tasks in the schedule, along with the creation of linkages between the predecessor and successor tasks, a critical path will become apparent. The critical path is formed by the longest chain, time wise, of interrelated tasks from the project start to the project finish. Basically, if any of the tasks in the longest chain were to take longer than their planned duration, the length of the project would be extended. The extension happens because the schedule slippage in one component in the critical path will push back the start dates of that component’s successor tasks. Therefore, the project manager places a high priority on these critical tasks, in order to keep the project on schedule.

Tasks that are located off of the critical path will often contain what is known as float. Float is an important concept, and is basically spare time contained within tasks that are located outside of the critical path. For example, the installation of a building roof may be scheduled for four weeks but in reality it is only expected to take three weeks. The extra week is float contained within that task, and the actual duration of work may “float” within that time period, sliding backwards or forward as needed to accomplish the project goals. If a project task that contains float happens to run over schedule, it can use the float time to finish and not affect the completion of the overall project.

Resource Oriented Scheduling

A scheduling technique known as resource oriented scheduling may be used in projects where there is competition between tasks or components for project resources. Resources may be comprised of:

- Materials such as water or cement

- Specific labor types such as welders or machine operators

- Transportation resources such as access to construction elevators or cranes

Attempting to implement a CPM approach to scheduling when resources are limited is not always effective. A better approach may entail breaking the project in time periods or phases and calculating the resource demand during each phase. This would be followed with planning the application of the available resources to fill in the demand. Often, the layout of the initial schedule will expose resource gaps in the project. This provides the project manager with knowledge regarding the tasks that will require supplementation of existing resources or the transfer of excess resources to another portion of the project.

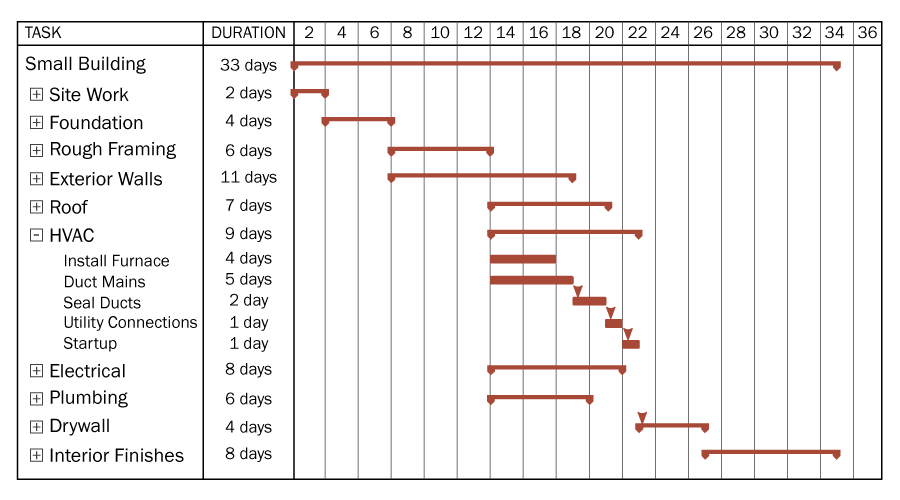

Visual Depiction of Schedule: Gantt Chart

Project schedules are most commonly depicted through the use of Gantt charts. Gantt charts break down the project into individual tasks, each of which is represented by a horizontal bar. The timescale of the project travels from left to right, with the left edge of the bar representing the start date of the task and the right edge of the bar representing the completion date. The bar length between the start and the end makes up the duration of that specific task. Arrows are typically drawn from the end of one task to the start of another task that is dependent on the task that proceeded it (predecessor to successor). Similar to the CPM method above, a critical path will become apparent based on the duration of the various linked project paths. Creation of a Gantt chart is relatively simple using commonly-available software, and the chart is easily modified during construction if needed due to unforeseen events or owner-driven changes. If the chart is set up correctly electronically, with the predecessors and successor links intact, the entire project schedule will adjust accordingly when the duration of one or more tasks is modified.

Design Scheduling

The methods above can also be used to develop your architectural project design schedule. All the concepts are the same, but the tasks and resources are different. These techniques are useful for project managers or for team use in a project kickoff meeting.